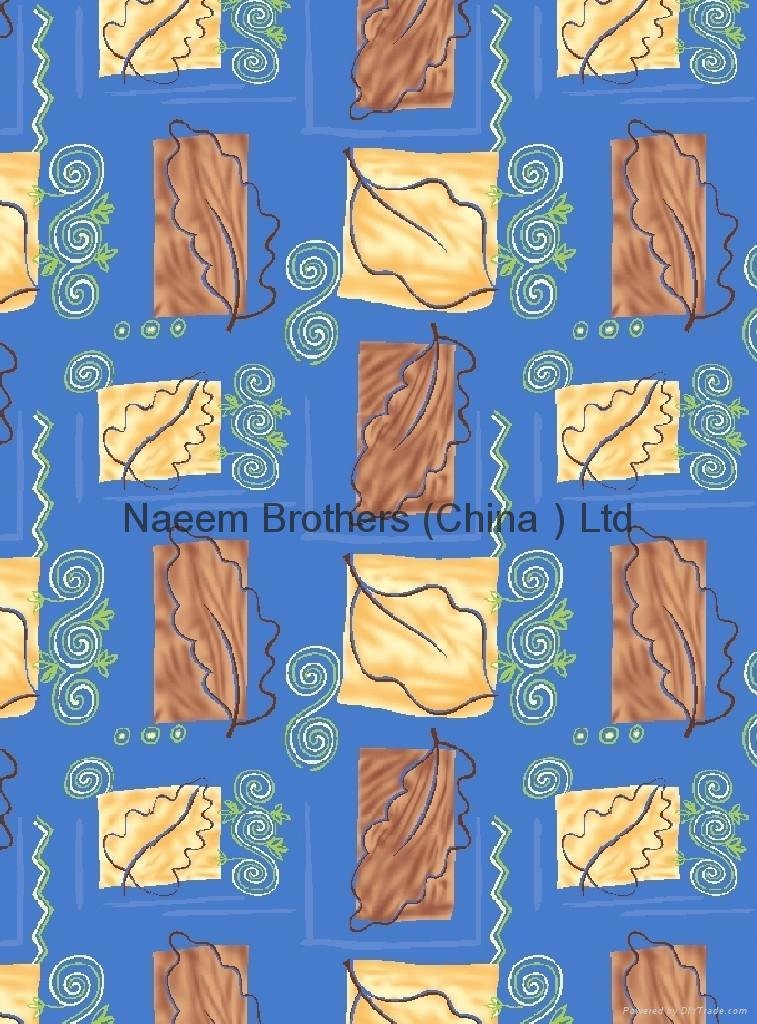

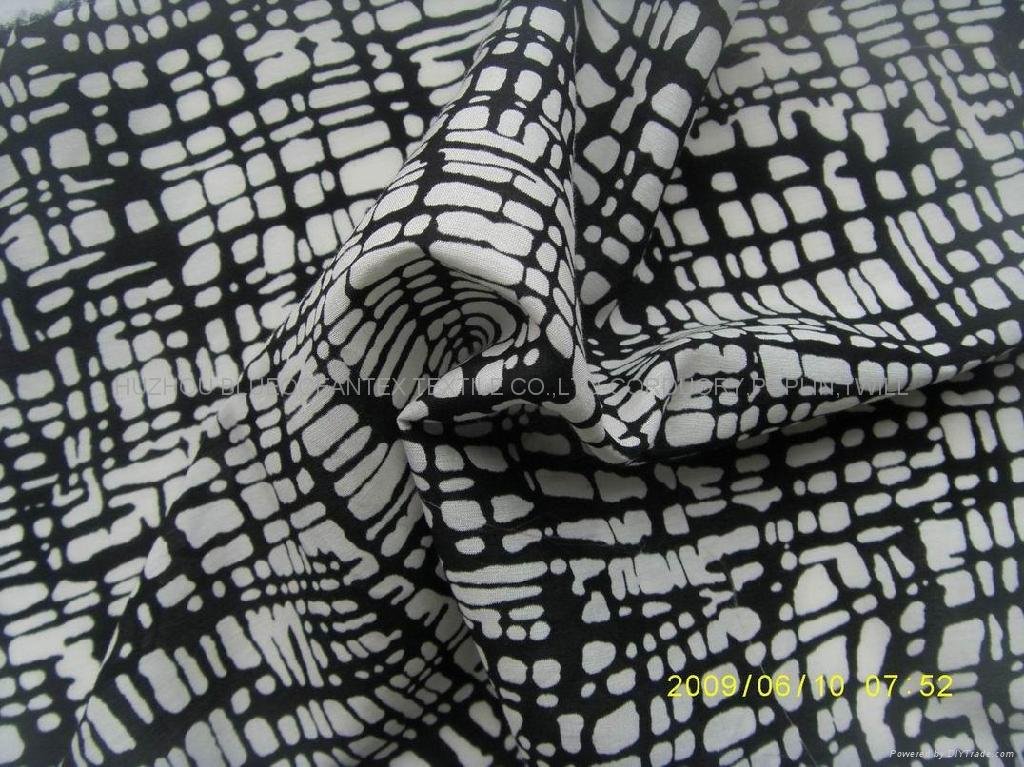

Textile Manufacturer Details

seed cotton goes in to a Cotton gin.

The cotton gin separates seeds and removes the "trash" (dirt, stems and

leaves) from the fibre. In a saw gin, circular saws grab the fibre and

pull it through a grating that is too narrow for the seeds to pass. A

roller gin is used with longer staple cotton. Here a leather roller

captures the cotton. A knife blade, set close to the roller, detaches

the seeds by drawing them through teeth in circular saws and revolving

brushes which clean them away.The ginned cotton fibre, known as lint, is then compressed into

bales which are about 1.5 m tall and weigh almost 220 kg. Only 33% of

the crop is usable lint. Commercial cotton is priced by quality, and

that broadly relates to the average length of the staple, and the

variety of the plant. Longer staple cotton (2½ in to 1¼ in) is called

Egyptian, medium staple (1¼ in to ¾ in) is called American upland and

short staple (less than ¾ in) is called Indian.

- The cotton seed is pressed into a cooking oil. The husks and meal are processed into animal feed, and the stems into paper.

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

Textile Manufacturer

No comments:

Post a Comment