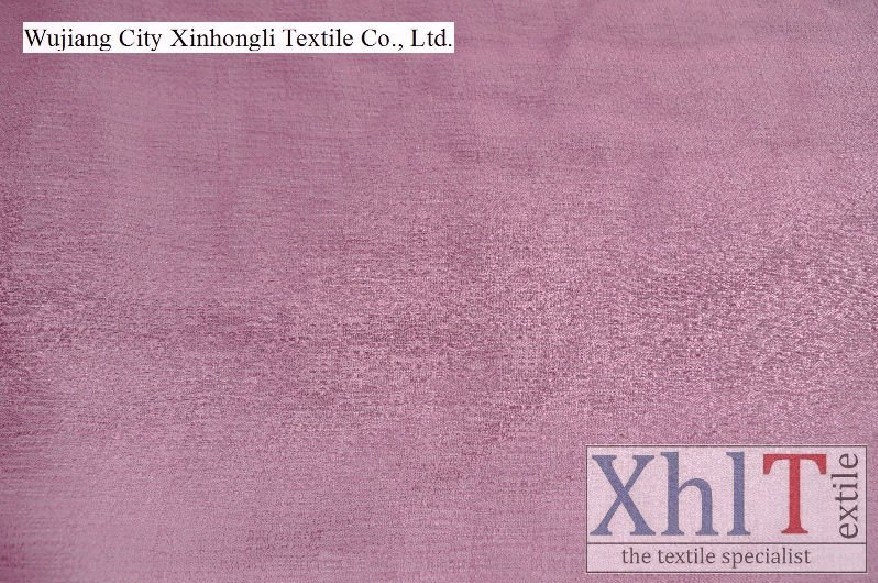

Crepo Fabrics Details

The wavy appearance of Canton crape results from the peculiar manner in which the weft

is prepared, the yarn from two bobbins being twisted together in the

reverse way. The fabric when woven is smooth and even, having no crape

appearance, but when the gum is subsequently extracted by boiling, it at

once becomes soft, and the weft, losing its twist, gives the fabric the

waved structure which constitutes its distinguishing feature. Canton

crapes are used, either white or colored, for scarves and shawls, bonnet trimmings, etc.The crisp and elastic structure of hard crape is not produced either in the spinning or in the weaving, but is due to processes through which the gauze passes after it is woven. In 1911, the details of these processes were known to only a few manufacturers, who so jealously guarded their secrets that, in some cases, the different stages in the manufacture were conducted in towns far removed from each other.[citation needed] Commercially they are distinguished as single, double, three-ply and four-ply crapes, according to the nature of the yarn used in their manufacture. They are almost exclusively dyed black and used in mourning dress.

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics

Crepo Fabrics